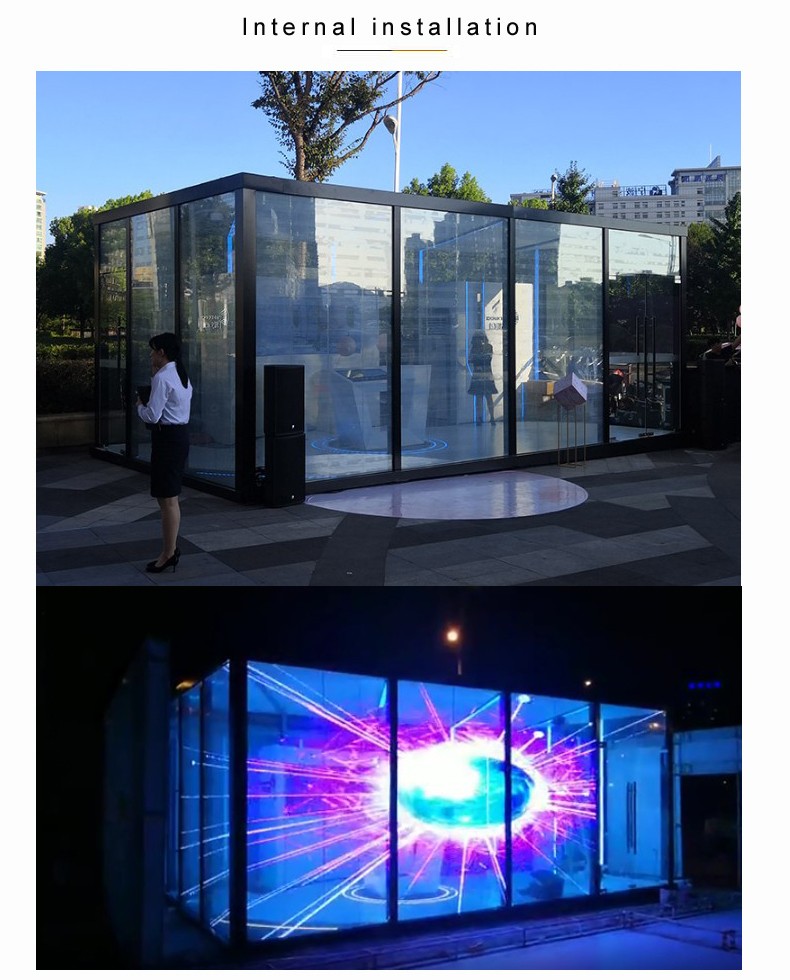

The LED crystal film screen adopts the bare crystal ball planting technology, the light board adopts a transparent crystal film film, the surface is etched with a transparent mesh circuit, and the surface is vacuum sealed after the components are pasted. The weight of thin led screen is extremely light, about 1.3kg/m² The crystal transparent led display are used in environments with glass, such as architectural glass curtain walls, glass showcases, glass guardrails, etc.

If you have any questions or need further information, please send an email to our Professional Marketing Manager (info@ty-leds.com), we will reply you as soon as possible. Thank you!

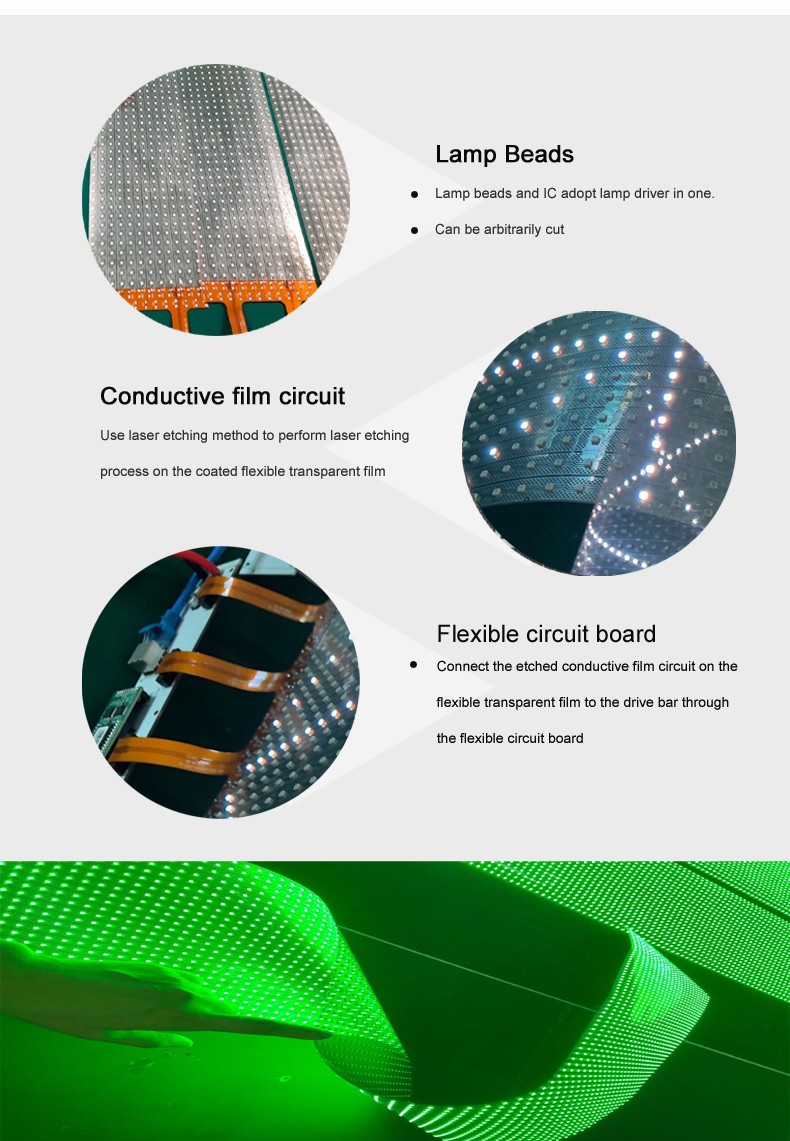

LED transparent thin film crystal film screen manufacturing:

1. Plating the conductive film material on the flexible transparent film, and the thickness of the conductive film is less than one order of magnitude lower than the thickness of the flexible transparent film;

2. Use laser etching method to perform laser etching process on the coated flexible transparent film to etch out the required connections between the LED chip pins to form a conductive film circuit;

3. Connect the LED chip to the flexible transparent film with etched conductive film circuit through ITO conductive electrode or conductive ink to form an LED flexible display, and paste a protective film on the LED flexible display;

4. Connect the etched conductive film circuit on the flexible transparent film to the drive bar through the flexible circuit board to form a complete display screen.

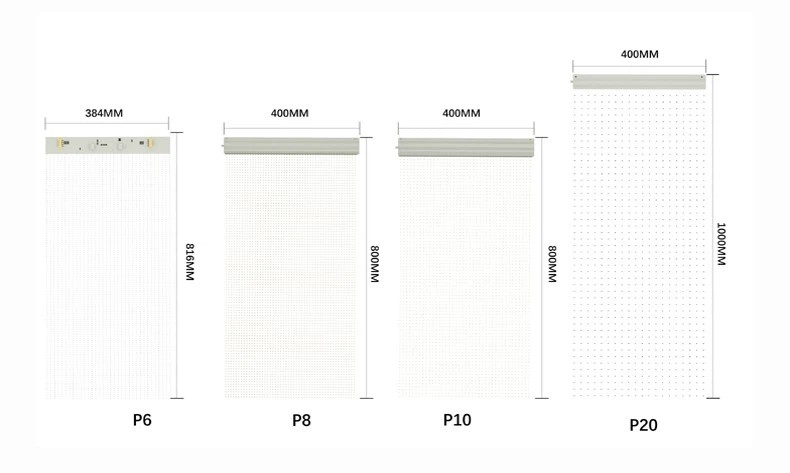

Pixel pitch | P6 | P8 | P10 | P20 |

LED model | SMD2020 R1G1B1 lamp IC drive in one | |||

Pixel density (dot/m²) | 27777 | 15625 | 10000 | 2500 |

Module ruler (WxHxD) | 816x204 | 800x400 | 800x400 | 960×240 |

Permeability | ≥80% | ≥88% | ≥90% | ≥94% |

Brightness (cd/㎡) | 800-5000 | 800-4000 | 800-4000 | 600-800 |

Screen weight | 1.5KG/㎡ | |||

Viewing angle | Horizontal 160°Vertical 160° | |||

Maximum power consumption | ≤600w/㎡ | |||

Average power consumption | ≤360w/㎡ | |||